PEC for CUI

Pulsed Eddy Current (PEC) for Corrosion Under Insulation (CUI)

Pulsed Eddy Current (PEC) is a technique that has been used for the screening of Corrosion Under Insulation (CUI) for several years. Only now is there a system that is capable of fast data acquisition capable of reading through 8” insulation and 2.5” of material.

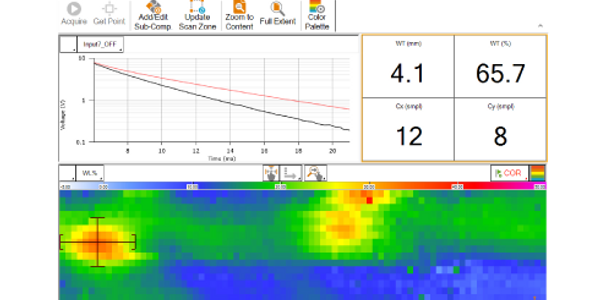

Thanks to Eddyfi’s Lyft system real time C-scan imaging and remaining wall measurements are attainable. PEC was designed for the screening of CUI, although internal process damage such as flow accelerated corrosion at elbows and other process damage can be assessed in one scan.

PEC uses low frequency eddy current ensuing no operator safety risks or environmental impact. With no radioactive exposure presenting potential risks, adjacent work or crafts can also be carried out during PEC examinations.

PEC can be used on insulated piping, equipment, sphere legs, fire proofing or through rugged coatings. These applications can become timely and costly to remove or replace with costs of scaffold, material and additional manpower.

New PEC technology gives you the advantage to obtain quantitative data to make timely safety and valuable operational decisions.